May 8, 2020 5:30:10 PM

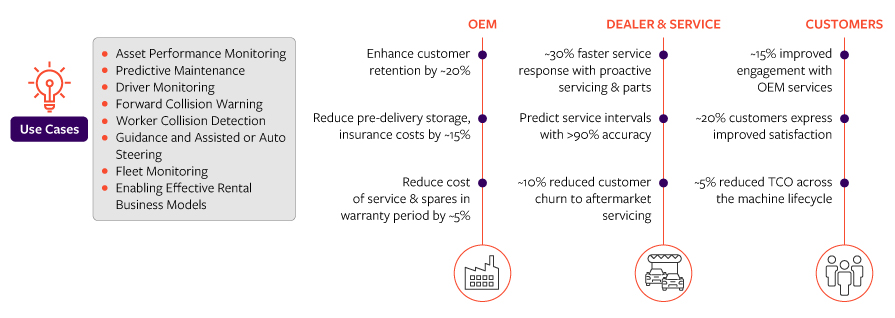

Multiple technologies such as Connectivity, Telematics, Smart HMIs, Cloud, ADAS, Machine Vision, and Advanced Analytics are being converged in the development of smarter off-highway vehicles. OEMs continually seek ways to utilize these technologies for effective redesign of products to keep up with customers’ needs and expectations while introducing new services. Construction, agricultural, and mining off-highway vehicles are becoming more complex and are expected to be more productive offering more features, consuming less fuel, reducing emissions, and ensuring safety. Companies normally compare the cost of technology implementation against the overall improvement in the equipment operation and the added value for business and customers. Market reports suggest that most OEMs will adopt embedded cellular connectivity across their products by 2025.

The next decade will see a rise in the adoption of smarter and connected off-highway vehicles offering competitive advantages through greater availability, greater productivity, higher performance, and enhanced operational experience. As per Counterpoint Research, a total of 6.8 million construction machines with embedded connectivity will be sold between 2018 and 2025 at a CAGR of 25%.

Smart Off-Highway Vehicles

Next-gen connected heavy machinery or smart off-highway vehicles are embedded with sensors measuring critical parameters, relaying information to telematics devices at defined intervals or when an abnormality is detected. The telematics device does Edge Analytics to monitor critical activities based on certain pre-determined parameters. At the same time, this data is also transferred to the Cloud via long-range connectivity technologies for Advanced Analytics. A Smart HMI within the machinery also provides critical information to the operator. They key technological components of smart off-highway vehicles are shown in the diagram below.

Click to Enlarge

Click to Enlarge· Predictive Maintenance of Off-Highway Vehicles:

IoT enabled autonomous vehicles typically have multiple internal sensors sensing the health of the engine and auxiliary equipment to get feedback for predictive maintenance. By monitoring patterns in real-time and by analyzing historical data, analytics and AI models can be built with rules created for predicting equipment failure. These rules keep improvising as more and more data and scenarios are encountered. A micro-service based application/interface can be used to view, monitor, and act upon key equipment health indicators from any remote location.

Once the predictions become more accurate, this data can be linked to ERP data, which would ensure the procurement of right spare parts, support services, etc. at the right time leading to reduced downtime and increased productivity.

· Fleet Management

One of the biggest challenges for fleet owners is gaining real-time visibility of productivity KPIs of equipment. They depend on site engineers to provide basic productivity KPIs, which is a manual process and prone to inaccuracy. With smart off-highway vehicles, it is possible to track various production KPIs for different off-highway equipment, making them available to fleet owners in real-time.

A few examples of productivity KPIs that can be measured and tracked using IoT, are quantity of concrete carried per trip and number of trips per day for transit mixers. For batching plants, metrics like quantity of concrete produced per hour and in a day can be measured. When it comes to tower cranes, metrics like weight lifted and number of lifts per day can be tracked leveraging IoT. The real-time availability of these different KPIs with the fleet owners allows them to take necessary interventions to drive productivity. As per certain reports, it can help increase the productive hours of their critical equipment by 65% and decrease idle hours by 33%.

· Enabling Effective Rental Business Models

Currently many off-highway vehicles are provided on rent to the contractors for a fixed amount of time to use in a particular operation with no possibility of tracking usage. Next-generation connected off-highway vehicles can change the revenue operational model of the company, wherein the rent can be based on the usage and the owner will be able to track if the machinery has been handled unprofessionally by the renter.

Sasken’s services for off-highway vehicles provide a solid foundation for supporting customers enabling next-gen heavy machinery. Sasken has have partnered with heavy machinery manufacturers across the globe and worked across the value chain from developing telematics units and HMIs to IoT Platform engineering. Among other benefits, Sasken has also helped customers, shift from reactive maintenance to proactive maintenance, thereby reducing downtime.

May 8, 2020 5:30:10 PM

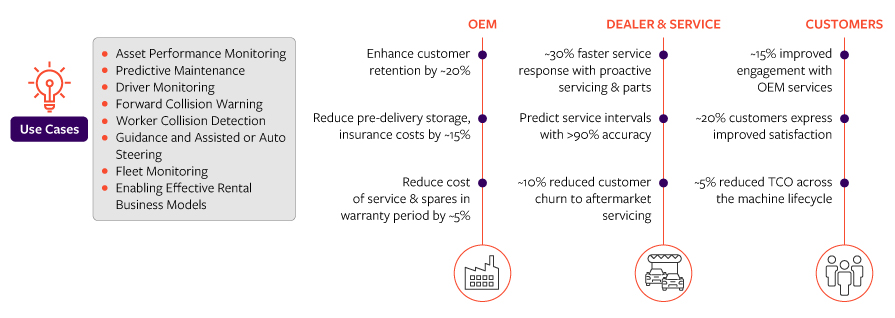

Multiple technologies such as Connectivity, Telematics, Smart HMIs, Cloud, ADAS, Machine Vision, and Advanced Analytics are being converged in the development of smarter off-highway vehicles. OEMs continually seek ways to utilize these technologies for effective redesign of products to keep up with customers’ needs and expectations while introducing new services. Construction, agricultural, and mining off-highway vehicles are becoming more complex and are expected to be more productive offering more features, consuming less fuel, reducing emissions, and ensuring safety. Companies normally compare the cost of technology implementation against the overall improvement in the equipment operation and the added value for business and customers. Market reports suggest that most OEMs will adopt embedded cellular connectivity across their products by 2025.

The next decade will see a rise in the adoption of smarter and connected off-highway vehicles offering competitive advantages through greater availability, greater productivity, higher performance, and enhanced operational experience. As per Counterpoint Research, a total of 6.8 million construction machines with embedded connectivity will be sold between 2018 and 2025 at a CAGR of 25%.

Smart Off-Highway Vehicles

Next-gen connected heavy machinery or smart off-highway vehicles are embedded with sensors measuring critical parameters, relaying information to telematics devices at defined intervals or when an abnormality is detected. The telematics device does Edge Analytics to monitor critical activities based on certain pre-determined parameters. At the same time, this data is also transferred to the Cloud via long-range connectivity technologies for Advanced Analytics. A Smart HMI within the machinery also provides critical information to the operator. They key technological components of smart off-highway vehicles are shown in the diagram below.

Click to Enlarge

Click to Enlarge· Predictive Maintenance of Off-Highway Vehicles:

IoT enabled autonomous vehicles typically have multiple internal sensors sensing the health of the engine and auxiliary equipment to get feedback for predictive maintenance. By monitoring patterns in real-time and by analyzing historical data, analytics and AI models can be built with rules created for predicting equipment failure. These rules keep improvising as more and more data and scenarios are encountered. A micro-service based application/interface can be used to view, monitor, and act upon key equipment health indicators from any remote location.

Once the predictions become more accurate, this data can be linked to ERP data, which would ensure the procurement of right spare parts, support services, etc. at the right time leading to reduced downtime and increased productivity.

· Fleet Management

One of the biggest challenges for fleet owners is gaining real-time visibility of productivity KPIs of equipment. They depend on site engineers to provide basic productivity KPIs, which is a manual process and prone to inaccuracy. With smart off-highway vehicles, it is possible to track various production KPIs for different off-highway equipment, making them available to fleet owners in real-time.

A few examples of productivity KPIs that can be measured and tracked using IoT, are quantity of concrete carried per trip and number of trips per day for transit mixers. For batching plants, metrics like quantity of concrete produced per hour and in a day can be measured. When it comes to tower cranes, metrics like weight lifted and number of lifts per day can be tracked leveraging IoT. The real-time availability of these different KPIs with the fleet owners allows them to take necessary interventions to drive productivity. As per certain reports, it can help increase the productive hours of their critical equipment by 65% and decrease idle hours by 33%.

· Enabling Effective Rental Business Models

Currently many off-highway vehicles are provided on rent to the contractors for a fixed amount of time to use in a particular operation with no possibility of tracking usage. Next-generation connected off-highway vehicles can change the revenue operational model of the company, wherein the rent can be based on the usage and the owner will be able to track if the machinery has been handled unprofessionally by the renter.

Sasken’s services for off-highway vehicles provide a solid foundation for supporting customers enabling next-gen heavy machinery. Sasken has have partnered with heavy machinery manufacturers across the globe and worked across the value chain from developing telematics units and HMIs to IoT Platform engineering. Among other benefits, Sasken has also helped customers, shift from reactive maintenance to proactive maintenance, thereby reducing downtime.