Feb 24, 2020 3:44:53 PM

Growth of Data Science in Vehicles

In recent times, the need for comfort and convenience along with driver assistance and safety has led to massive utilization of cross domain intelligence in vehicles. Vehicles nowadays not only monitor external entities, but also their occupants to mitigate injuries due to unforeseen road incidents. Cameras, radars and ultrasonic sensors have gained traction to enable the same. However, newer Lidars and sonars have not been entrenched due to the cost factors involved in their integration and utilization. The Electronic Control Units (ECUs) also need to handle data from these sensors and prompt the driver to take control, thereby preventing undesirable outcomes.

This data explosion, led to automation of actuators like brakes, steering control and door opening during emergency situations to become an industry norm. Governments started regulating these needs as a part of the Motor Vehicle and Road Safety Regulations. This paved the way for more stringent coding guidelines to be followed like MISRA and massive test-driven development. They are carried out on Hardware-in-Loop Simulators along with road tests and NCAPs (New Car Assessment Programs) before being released. The main takeaway was that OEMs and Tier-1s along with AUTOSAR started imposing safety goals and implementing them in terms of functional and non-functional requirements. This also led to the creation of a FuSa (Functional Safety) standard following best practices from IEC 61508, discussed previously.

Data teams within the Automotive industry also started growing in clusters following the ideology “Data is the new oil”. Environment regulatory boards began analyzing exhaust pipes per vehicle, rather than just factory emissions. This led to a massive overhaul of the under-utilization of powerful gasoline or diesel engines. The rise in crude oil prices also contributed towards seeking alternative fuels; and then came hybrid and electric vehicles. As of January 2020, Tesla alone has contributed the maximum turnover in the history of electric vehicles. This data explosion also introduced the risk of exposing vehicle data to nefarious communities online. To combat the same, cyber security experts were looped into the ecosystem, implementing similar security standards as seen across the internet and for banking, nuclear, and government bodies. Typically cyber security in-vehicles were handled by limiting exposures to safety critical hardware infrastructure within vehicles. This included hypervisors, communication firewalls, secure chip to chip communication and E2E protection to name a few.

Entry of Adaptive AUTOSAR and SOTIF

The data explosion also led to massive middleware software AUTOSAR architecture which became increasingly difficult to handle for both man-made and machine-made (vehicles in sum or parts) errors. The complexity was such that, at one point of time the lines of codes on a fully functional car like Daimler had around 200 million lines. A stark contrast when compared to an F-35 jet which had around 20 million lines. This 10X complexity of software and hardware management resulted in the release of intermediate software architecture in AUTOSAR called Adaptive AUTOSAR. The software complexities were handled via a massively parallel in-vehicle infrastructure, with some functionality off the vehicle in a cloud-based infrastructure. There were further contributions from other parallel developments in industries like IoT, Cloud, AI/ML/DL and Industry 4.0. They provided the basis for a new architecture decoupled for the sake of computing infrastructure needs and data handling. It also paved the way for replaying road video and accident data into the Hardware-in-Loop environments to provide a safety critical simulation beforehand. The need for a less time critical OS gave way for a POSIX based realization of OS in the Adaptive AUTOSAR. However, it decoupled itself from the safety critical sensors and actuators categorized under higher ASIL (Automotive Safety Integrity Level) factor by FuSa norms.

The newest entry into the vehicle Functional Safety is the ISO/PAS 21448 regulation categorized and recognized as SOTIF (Safety of The Intended Functionality ISO/PAS 21448). This regulation clearly incorporates all the above discussed features needed to protect and prevent vehicle fatalities in Autonomous Vehicles. It focuses on both sides of the widely practiced V-software architecture model practices. The design aspects of the sensors and actuators come under the left side of this system in vehicle engineering. The unit to vehicle level testing aspects falling in the right side of the model. It incorporates the existing data from roads and accidents, MISRA and other software development along with unit testing guidelines and essential Hardware-in-Loop testing. By doing so, it focuses on the intended functionality of the autonomous system being incorporated into the vehicle.

The automotive industry can be perceived as a backbone which all nations, industries, businesses, and consumers rely on. Its complexity can lead to it being considered equivalent to the general population as we look towards the advent of new man-machine parallel ecosystems and smart cities.

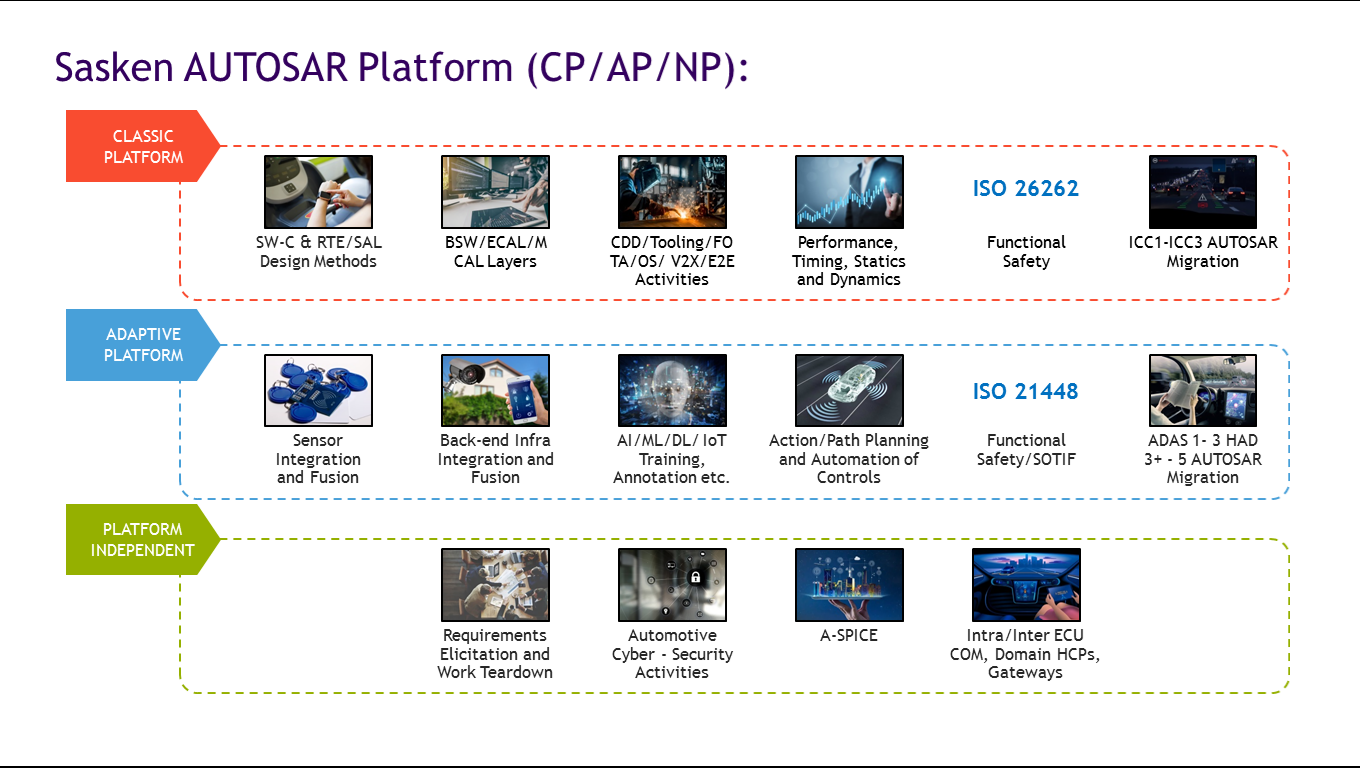

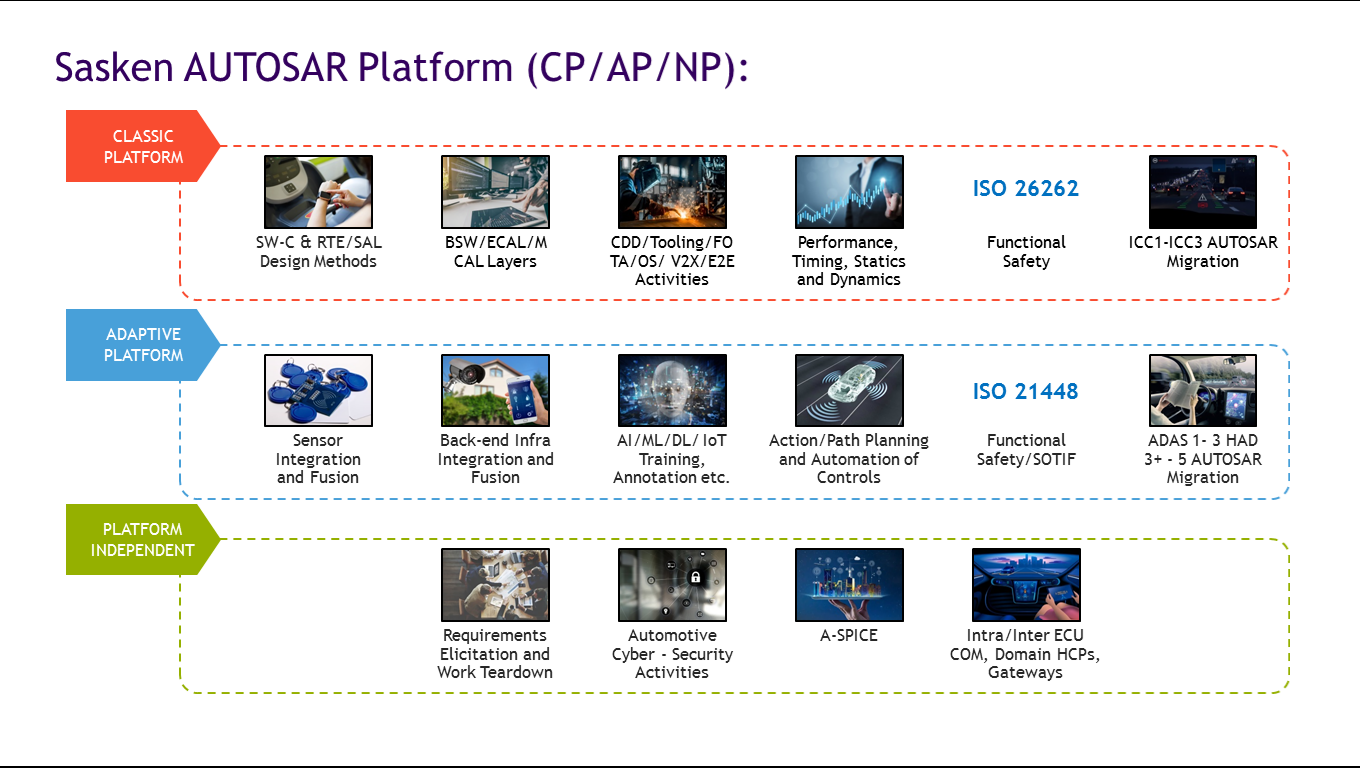

How Sasken Can Support AUTOSAR Ecosystem Partners

Learn more about Sasken’s comprehensive skillset in developing autonomous vehicles for the future.

Feb 24, 2020 3:44:53 PM

Growth of Data Science in Vehicles

In recent times, the need for comfort and convenience along with driver assistance and safety has led to massive utilization of cross domain intelligence in vehicles. Vehicles nowadays not only monitor external entities, but also their occupants to mitigate injuries due to unforeseen road incidents. Cameras, radars and ultrasonic sensors have gained traction to enable the same. However, newer Lidars and sonars have not been entrenched due to the cost factors involved in their integration and utilization. The Electronic Control Units (ECUs) also need to handle data from these sensors and prompt the driver to take control, thereby preventing undesirable outcomes.

This data explosion, led to automation of actuators like brakes, steering control and door opening during emergency situations to become an industry norm. Governments started regulating these needs as a part of the Motor Vehicle and Road Safety Regulations. This paved the way for more stringent coding guidelines to be followed like MISRA and massive test-driven development. They are carried out on Hardware-in-Loop Simulators along with road tests and NCAPs (New Car Assessment Programs) before being released. The main takeaway was that OEMs and Tier-1s along with AUTOSAR started imposing safety goals and implementing them in terms of functional and non-functional requirements. This also led to the creation of a FuSa (Functional Safety) standard following best practices from IEC 61508, discussed previously.

Data teams within the Automotive industry also started growing in clusters following the ideology “Data is the new oil”. Environment regulatory boards began analyzing exhaust pipes per vehicle, rather than just factory emissions. This led to a massive overhaul of the under-utilization of powerful gasoline or diesel engines. The rise in crude oil prices also contributed towards seeking alternative fuels; and then came hybrid and electric vehicles. As of January 2020, Tesla alone has contributed the maximum turnover in the history of electric vehicles. This data explosion also introduced the risk of exposing vehicle data to nefarious communities online. To combat the same, cyber security experts were looped into the ecosystem, implementing similar security standards as seen across the internet and for banking, nuclear, and government bodies. Typically cyber security in-vehicles were handled by limiting exposures to safety critical hardware infrastructure within vehicles. This included hypervisors, communication firewalls, secure chip to chip communication and E2E protection to name a few.

Entry of Adaptive AUTOSAR and SOTIF

The data explosion also led to massive middleware software AUTOSAR architecture which became increasingly difficult to handle for both man-made and machine-made (vehicles in sum or parts) errors. The complexity was such that, at one point of time the lines of codes on a fully functional car like Daimler had around 200 million lines. A stark contrast when compared to an F-35 jet which had around 20 million lines. This 10X complexity of software and hardware management resulted in the release of intermediate software architecture in AUTOSAR called Adaptive AUTOSAR. The software complexities were handled via a massively parallel in-vehicle infrastructure, with some functionality off the vehicle in a cloud-based infrastructure. There were further contributions from other parallel developments in industries like IoT, Cloud, AI/ML/DL and Industry 4.0. They provided the basis for a new architecture decoupled for the sake of computing infrastructure needs and data handling. It also paved the way for replaying road video and accident data into the Hardware-in-Loop environments to provide a safety critical simulation beforehand. The need for a less time critical OS gave way for a POSIX based realization of OS in the Adaptive AUTOSAR. However, it decoupled itself from the safety critical sensors and actuators categorized under higher ASIL (Automotive Safety Integrity Level) factor by FuSa norms.

The newest entry into the vehicle Functional Safety is the ISO/PAS 21448 regulation categorized and recognized as SOTIF (Safety of The Intended Functionality ISO/PAS 21448). This regulation clearly incorporates all the above discussed features needed to protect and prevent vehicle fatalities in Autonomous Vehicles. It focuses on both sides of the widely practiced V-software architecture model practices. The design aspects of the sensors and actuators come under the left side of this system in vehicle engineering. The unit to vehicle level testing aspects falling in the right side of the model. It incorporates the existing data from roads and accidents, MISRA and other software development along with unit testing guidelines and essential Hardware-in-Loop testing. By doing so, it focuses on the intended functionality of the autonomous system being incorporated into the vehicle.

The automotive industry can be perceived as a backbone which all nations, industries, businesses, and consumers rely on. Its complexity can lead to it being considered equivalent to the general population as we look towards the advent of new man-machine parallel ecosystems and smart cities.

How Sasken Can Support AUTOSAR Ecosystem Partners

Learn more about Sasken’s comprehensive skillset in developing autonomous vehicles for the future.